High-Quality Front End Loader Parts from Leading Manufacturers & Suppliers

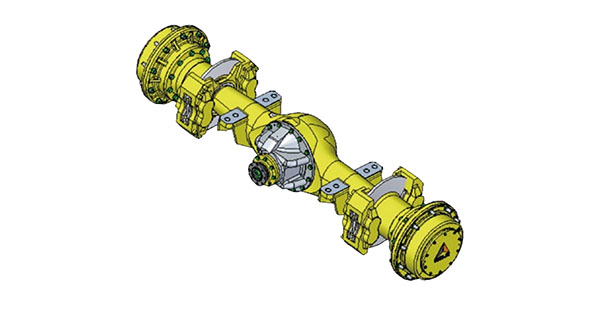

Linyi Weiman Import and Export Co., LTD. specializes in high-quality parts for front end loaders. Our extensive range includes buckets, hydraulic cylinders, cutting edges, and more, all designed to perform exceptionally in demanding conditions. Utilizing advanced manufacturing techniques and top-grade materials, our parts meet rigorous standards for durability and reliability. Whether you need replacement components or wish to enhance your front end loader’s performance, we provide compatible solutions for various models. With a commitment to customer satisfaction, Linyi Weiman ensures you receive reliable parts that keep your equipment operating efficiently. Contact us to learn more about how our front end loader parts can support your operations.Key Methods For Parts Of A Front End Loader Manufacturers Factory-Direct Excellence Service

At Linyi Weiman Import and Export Co., LTD, we pride ourselves on being a leading supplier of heavy construction equipment, delivering factory-direct excellence that resonates with global buyers. Our commitment to quality and service sets us apart in the competitive landscape of construction machinery. This excellence is founded on several key methods that have proven effective in ensuring our customers receive the best products and support. Firstly, we prioritize rigorous quality control at every stage of the manufacturing process. Our skilled workforce employs state-of-the-art technology to produce a range of equipment, including wheel loaders, backhoe loaders, skid steer loaders, and excavators. Our luxury mini loader is particularly popular among clients seeking versatility without sacrificing power. By maintaining high standards of quality, we ensure that our products are not only durable but also reliable in the most challenging working conditions. Secondly, our factory-direct service model guarantees that clients benefit from direct communication and transparency. We understand the significance of timely delivery and responsive customer support in international trade. Our team works closely with buyers to tailor solutions that meet their unique needs, ensuring a seamless purchasing experience. With Linyi Weiman, you’re not just buying equipment; you’re investing in a partnership that prioritizes your operational success. Discover the difference of partnering with a manufacturer that is dedicated to your excellence.

Key Methods For Parts Of A Front End Loader Manufacturers Factory-Direct Excellence Service

| Method | Description | Benefits | Implementation Frequency |

|---|---|---|---|

| Quality Control | Regular inspection of parts and components during production. | Ensures high durability and performance standards. | Ongoing |

| Lean Manufacturing | Optimization of production processes to reduce waste. | Increases efficiency and reduces costs. | Monthly reviews |

| Supplier Evaluation | Assessing supplier performance and material quality. | Strengthens supply chain reliability. | Quarterly |

| Employee Training | Continuous education on safety and equipment handling. | Reduces accidents and improves productivity. | Biannually |

| Maintenance Schedule | Regular checks and repairs on machinery. | Prolongs equipment lifespan and reduces downtime. | Weekly |

How-To Guide Parts Of A Front End Loader Manufacturers Where Service Meets Innovation Is The Best

E

Emily Wright

Fantastic product! After-sales personnel were extremely professional and helped tremendously.

10 June 2025

W

William Harris

Very happy with my purchase! The quality is outstanding, and the support team is very efficient.

28 May 2025

Z

Zoe Allen

I’m thoroughly satisfied! The product quality is exceptional, and service was impeccable.

23 May 2025

G

Gabriel Edwards

Very satisfied with my product! The support team was highly professional and efficient.

04 July 2025

S

Samantha Wood

Truly impressed with the item’s quality and the after-sales service was superb.

28 June 2025

V

Victoria Murphy

Remarkable quality! The after-sales staff was professional, friendly, and very helpful.

26 June 2025

Wheel Loader

Wheel Loader  Excavator

Excavator  Motor Grader

Motor Grader  Backhoe Loader

Backhoe Loader  Road Roller

Road Roller  Spare Parts

Spare Parts