High-Quality Wheel Loader Maintenance: Top Manufacturers & Trusted Brands

Linyi Weiman Import and Export Co., LTD. is a leading manufacturer specializing in wheel loader maintenance. Our expert services cater to all major brands and models, ensuring that your equipment remains in top working condition. We provide comprehensive maintenance programs designed to enhance efficiency and reduce downtime. Our trained technicians and engineers are committed to delivering high-quality maintenance services, including regular inspections, parts replacements, and repairs. At Linyi Weiman, we prioritize the performance and longevity of your wheel loaders. Count on us for reliable maintenance solutions that keep your operations running smoothly.Insider tips For Wheel Loader Maintenance Manufacturer For the Current Year Where Service Meets Innovation

In the ever-evolving landscape of heavy construction equipment, maintaining the efficiency and longevity of your wheel loaders is critical for optimal performance and cost-effectiveness. As a global leader in the construction equipment supply industry, Linyi Weiman Import and Export Co., LTD understands the importance of innovative maintenance strategies that effectively blend traditional servicing with cutting-edge technology. For procurement specialists seeking reliable wheel loader maintenance tips, it’s essential to emphasize the significance of routine inspections and preventative care. Regular checks on hydraulic systems, engine performance, and tire conditions can prevent costly downtime and prolong the life of your machinery. Incorporating smart technology, such as telematics systems, allows for real-time monitoring of machine health, providing insights that lead to proactive maintenance decisions tailored to specific operational needs. Innovation in servicing cannot be overlooked. Weiman champions the integration of digital solutions to streamline maintenance processes. This not only enhances service efficiency but also allows manufacturers and operators to track maintenance history and schedules more effectively. Investing in modern service techniques and staying up-to-date with the latest advancements ensures that you get the most out of your wheel loaders, making them more reliable and productive on the job site. By prioritizing these insider maintenance tips, global buyers can ensure their fleet remains at the forefront of performance in 2023 and beyond.

Insider Tips For Wheel Loader Maintenance Manufacturer For the Current Year Where Service Meets Innovation

| Maintenance Tip | Frequency | Best Practices | Innovative Tools |

|---|---|---|---|

| Regular Oil Changes | Every 250 hours | Use high-quality oil and filters | Oil analysis kits |

| Inspect Hydraulic Systems | Monthly | Check for leaks and proper fluid levels | Pressure gauges |

| Tire Maintenance | Weekly | Check tire pressure and tread | Inflation monitoring systems |

| Cooling System Checks | Every 500 hours | Flush and replace coolant as needed | Coolant level sensors |

| Operator Training | Ongoing | Ensure operators are properly trained | Training simulators |

Today's Choice of Wheel Loader Maintenance Manufacturer Guarantees Peak Performance Service Backed by Expertise

N

Noah Wilson

The item exceeded my expectations in quality. The team was very professional and attentive!

17 June 2025

A

Amelia Hall

This product’s quality is remarkable! I admire the professionalism displayed by the support staff.

10 June 2025

W

William Harris

Very happy with my purchase! The quality is outstanding, and the support team is very efficient.

28 May 2025

L

Leo Reed

Amazing quality! The customer service staff were exceptional in addressing my needs.

08 June 2025

E

Eli Cooper

This product is a fantastic investment! Qualified support helped me significantly.

26 May 2025

L

Luca Young

The quality of this product is impressive! The after-sales team was professional and very helpful.

17 June 2025

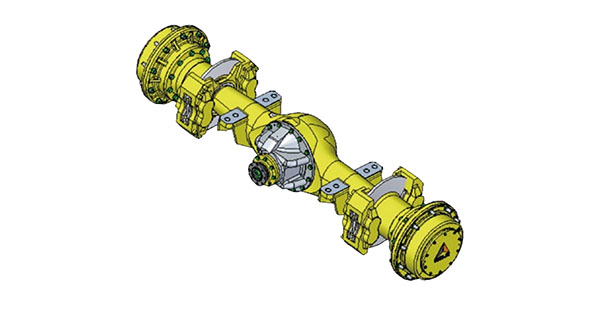

Wheel Loader

Wheel Loader  Excavator

Excavator  Motor Grader

Motor Grader  Backhoe Loader

Backhoe Loader  Road Roller

Road Roller  Spare Parts

Spare Parts