United Heavy Industries: Premium Quality Products from Leading Factories Worldwide

Welcome to United Heavy Industries, a manufacturer dedicated to providing top-tier heavy-duty machinery and equipment through Linyi Weiman Import and Export Co., LTD. Our extensive product lineup includes hydraulic excavators, wheel loaders, bulldozers, and motor graders, all tailored to meet the demands of various industries. As an industry leader, we focus on delivering high-quality, durable, and reliable machinery designed to thrive in the toughest environments. Known for their outstanding performance, efficiency, and cutting-edge technology, our products represent a significant investment for any industrial operation. Choose United Heavy Industries for superior quality and performance in heavy machinery.

10 tips United Heavy Industries Manufacturer Outperforms the Competition From Concept to Delivery

In the competitive landscape of heavy construction equipment manufacturing, United Heavy Industries stands out by mastering the art of delivering exceptional products from concept to delivery. As a top professional construction equipment supplier based in Linyi, Shandong province, Weiman Import and Export Co., LTD embraces a commitment to quality and innovation that mirrors the strategies adopted by industry leaders. One of the critical tips for success is focusing on customer needs. By engaging closely with clients, Weiman ensures that its wheel loaders, luxury mini loaders, backhoe loaders, skid steer loaders, excavators, and motor graders are tailored to meet diverse requirements. This customer-centric approach not only fosters long-term relationships but also enhances product relevance in various markets. Furthermore, the integration of cutting-edge technology in the manufacturing process significantly boosts efficiency and reliability, allowing Weiman to maintain a competitive edge. Finally, an unwavering dedication to on-time delivery encapsulates Weiman's operational excellence. By optimizing logistics and supply chain management, the company guarantees that global purchasers receive their heavy construction equipment promptly, thus minimizing downtime at job sites. As businesses worldwide seek dependable partners, Weiman's strategic focus on these key areas illustrates how thoughtful manufacturing and a commitment to service can lead to industry leadership.

10 Tips United Heavy Industries Manufacturer Outperforms the Competition From Concept to Delivery

| Tip Number | Tip Description | Expected Outcome | Implementation Timeline |

|---|---|---|---|

| 1 | Utilize Advanced CAD Software for Design | Higher design accuracy and reduced revisions | 1 month |

| 2 | Implement Lean Manufacturing Principles | Reduced waste and increased efficiency | 6 months |

| 3 | Incorporate Automated Production Lines | Faster production and decreased labor costs | 1 year |

| 4 | Enhance Quality Control Processes | Fewer defects and improved product reliability | 3 months |

| 5 | Focus on Sustainable Manufacturing Practices | Reduced environmental impact and improved brand image | Ongoing |

| 6 | Invest in Employee Training Programs | Higher skill levels and better overall performance | 2 months |

| 7 | Utilize Customer Feedback for Product Development | Products that better meet customer needs | 3 months |

| 8 | Adopt Real-time Project Management Tools | Improved project tracking and deadlines | 1 month |

| 9 | Develop Strategic Partnerships | Access to new markets and resources | Ongoing |

| 10 | Enhance Supply Chain Management | Reduced costs and improved delivery times | 6 months |

Ultimate Guide To United Heavy Industries Manufacturer Where Innovation Meets 2025 Manufacturer

J

Jackson Martinez

I appreciate the excellent quality of the product and the professional after-sales service.

13 May 2025

D

Dominic Bell

Very satisfied with my purchase! The professionalism of the customer support was noted.

25 May 2025

I

Isaac Hayes

Quality exceeds expectations! The support team handled my inquiries with professionalism.

09 June 2025

B

Brandon Palmer

A top-grade purchase! The service team addressed my needs promptly and professionally.

23 June 2025

C

Chase Stewart

Outstanding quality! The support team was very professional and helpful.

22 June 2025

H

Hazel Bell

Fantastic item! The quality is top-notch, and support staff was attentive.

18 June 2025

Wheel Loader

Wheel Loader  Excavator

Excavator  Motor Grader

Motor Grader  Backhoe Loader

Backhoe Loader  Road Roller

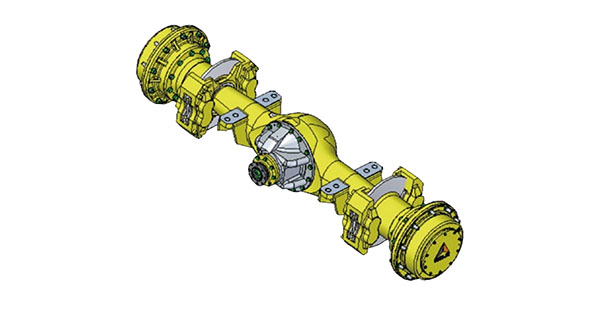

Road Roller  Spare Parts

Spare Parts