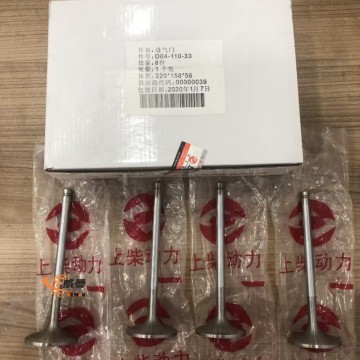

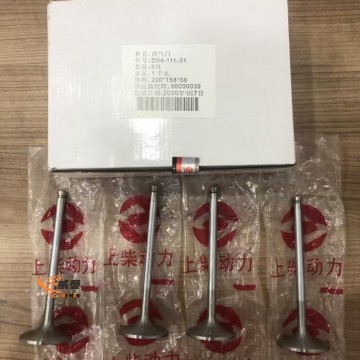

Weichai Intake Valve Guide - Wholesale from Top Factories & Trusted Manufacturers

The Weichai Intake Valve Guide is your go-to choice for reliable engine components. Manufactured in a cutting-edge facility in China, this valve guide is engineered for exceptional performance and longevity. With a commitment to quality and years of industry expertise, this product ensures precise fitting and optimal functionality, enhancing your engine's efficiency. Ideal for B2B purchasers, this robust valve guide is designed to withstand the demands of everyday operations, offering lasting value and performance you can trust.10 Essential tips For Weichai Intake Valve Guide From Concept to Delivery Guarantees Peak Performance

When it comes to ensuring the optimum performance of heavy construction equipment, attention to detail is paramount. The intake valve guide plays a crucial role in maintaining engine efficiency, and understanding its significance is vital for global buyers in the construction machinery sector. This guide outlines essential tips for navigating the development and procurement of high-quality intake valve guides, from concept to delivery, helping you secure the best components for your equipment. First, prioritize the selection of durable materials that can withstand the rigors of heavy operation. Utilizing advanced manufacturing techniques will ensure precision and longevity in performance. Additionally, understanding the design specifications required for various machinery is essential. Collaborating with knowledgeable suppliers who can provide insights and recommendations tailored to your equipment needs will pave the way for effective solutions. Finally, pay attention to the logistics involved in the delivery of these components. Timely procurement and reliable shipping strategies are critical to minimizing downtime and enhancing productivity at job sites. Establishing strong partnerships with suppliers who understand the global supply chain dynamics can lead to more efficient processes. By following these key tips, you can guarantee peak performance from your heavy construction equipment while optimizing your procurement strategy.

10 Essential Tips For Weichai Intake Valve Guide From Concept to Delivery Guarantees Peak Performance

| Tip No. | Tip Description | Expected Outcome |

|---|---|---|

| 1 | Conduct comprehensive material analysis for intake valve guides. | Improved durability and resistance to wear. |

| 2 | Utilize advanced CAD software for design validation. | Higher accuracy in production dimensions. |

| 3 | Perform prototype testing under various conditions. | Identification of potential failure points. |

| 4 | Integrate feedback from manufacturing into design. | Streamlined production processes. |

| 5 | Ensure tight tolerances during machining processes. | Enhanced fit and function of components. |

| 6 | Implement rigorous quality control measures. | Reduced defect rates in final products. |

| 7 | Optimize surface treatment processes. | Improved corrosion resistance. |

| 8 | Collaborate with OEMs for tailored specifications. | Products that meet specific application requirements. |

| 9 | Plan for scalability in production capacity. | Ability to meet growing market demands. |

| 10 | Establish a robust logistics and delivery framework. | Timely delivery and improved customer satisfaction. |

Must-See List Weichai Intake Valve Guide From Concept to Delivery Manufacturers You Can Rely On

E

Ethan Garcia

This product is one of the best I have purchased. The customer service was outstanding!

24 June 2025

C

Charlotte Lewis

The craftsmanship is excellent! Customer support was quick to respond and very friendly.

28 June 2025

W

Wyatt Hall

A quality product with excellent after-sales service. The team was very professional.

07 July 2025

A

Aubrey Morgan

Fantastic craftsmanship! The service team was attentive and offered great assistance.

16 May 2025

G

Gabriel Nguyen

The product quality is fantastic! The after-sales team provided excellent support.

26 June 2025

B

Bella James

Thoroughly pleased! The support team was knowledgeable and very responsive.

21 June 2025

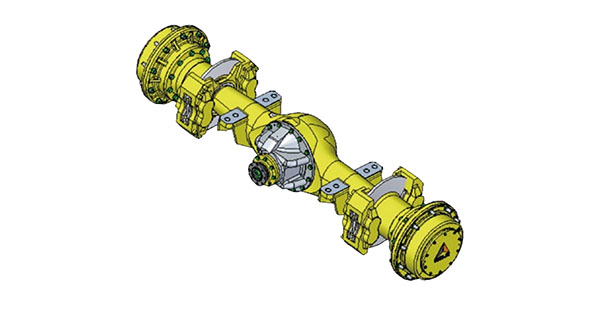

Wheel Loader

Wheel Loader  Excavator

Excavator  Motor Grader

Motor Grader  Backhoe Loader

Backhoe Loader  Road Roller

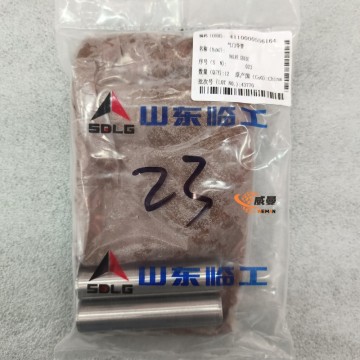

Road Roller  Spare Parts

Spare Parts