High-Quality Oil Pump Sub-Assemblies from a Leading Manufacturer and Supplier

Are you seeking high-quality oil pump sub-assemblies at competitive prices? At Linyi Weiman Import and Export Co., LTD., we specialize in delivering reliable and high-performance components tailored to meet your operational needs. Our oil pump sub-assemblies are meticulously crafted to adhere to stringent industry standards, ensuring the utmost quality and satisfaction. With years of experience in the field, we cater to a wide range of requirements for manufacturers and retailers alike. Committed to providing exceptional service and support, we are ready to assist you in enhancing your product offerings. Contact us for more information on how we can partner together for your success.10 tips Oil Pump Sub-Assembly Trusted by Pros Manufacturers You Can Rely On

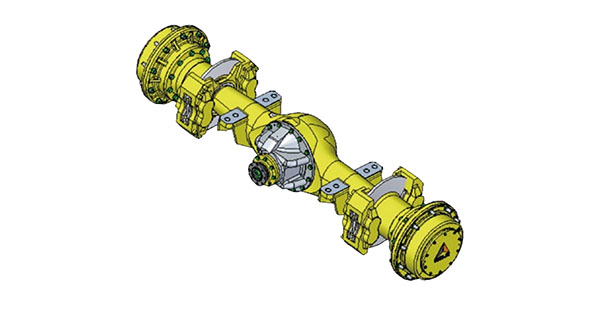

When it comes to sourcing reliable oil pump sub-assemblies, manufacturers and procurement professionals understand the importance of quality and trustworthiness in their suppliers. Linyi Weiman Import and Export Co., LTD, located in Linyi City, Shandong Province, stands out as a top-tier provider in the heavy construction equipment sector. With a strong emphasis on delivering only the best products, Weiman has become a trusted name among global buyers seeking essential components that support their operations. Weiman's commitment to excellence is reflected in its extensive range of heavy construction equipment, including wheel loaders, luxury mini loaders, backhoe loaders, skid steer loaders, excavators, and motor graders. Each of these machines is designed with high-performance components, ensuring exceptional durability and reliability on the job site. By partnering with Weiman, manufacturers gain access to top-quality oil pump sub-assemblies crafted with precision and attention to detail, essential for maintaining optimal equipment performance and extending machinery lifespan. By choosing Linyi Weiman as your supplier, you are not just purchasing a product; you are investing in a long-term relationship characterized by trust, quality, and responsiveness. Weiman’s team of experts is dedicated to providing personalized service, helping global buyers navigate their unique requirements and ensuring they receive the right solutions to enhance their construction projects. For those seeking dependable oil pump sub-assemblies and heavy construction equipment, Linyi Weiman is the partner you can rely on.

10 Tips Oil Pump Sub-Assembly Trusted by Pros Manufacturers You Can Rely On

| Tip | Description | Benefit |

|---|---|---|

| 1. Use Quality Materials | Always select high-grade metals and plastics for durability. | Enhances the longevity and reliability of pumps. |

| 2. Precision Engineering | Employ advanced machining techniques for component accuracy. | Reduces the risk of malfunction and improves performance. |

| 3. Regular Testing | Implement rigorous quality testing during assembly. | Ensures every pump meets operational standards. |

| 4. Routine Maintenance | Schedule regular maintenance checks on pumps. | Prolongs pump life and prevents unexpected failures. |

| 5. Training Personnel | Train staff on proper assembly and handling techniques. | Boosts efficiency and reduces human errors. |

| 6. Quality Control Metrics | Utilize key performance indicators (KPIs) for tracking. | Improves the monitoring of assembly line efficiency. |

| 7. Incorporate Technology | Leverage automation tools for repetitive tasks. | Increases throughput and precision in assembly. |

| 8. Inventory Management | Maintain optimum stock levels of parts and materials. | Minimizes downtime due to shortages. |

| 9. Cross-Functional Collaboration | Encourage teamwork among engineering and production. | Fosters innovation and improves problem-solving. |

| 10. Customer Feedback | Gather insights from users to refine products. | Enhances product development and satisfaction. |

Methods To Oil Pump Sub-Assembly Global Reach Where Service Meets Innovation

D

David Smith

Top-notch product quality! The staff in customer support were both professional and courteous.

24 May 2025

A

Avery Thompson

Impressive quality! The customer service team demonstrated great expertise and support.

07 May 2025

S

Samantha Wood

Truly impressed with the item’s quality and the after-sales service was superb.

28 June 2025

K

Kevin Lopez

Great quality and efficiency! The customer service team was informative and supportive.

14 May 2025

K

Kimberly Jenkins

Top-notch item! The support team displayed expertise in resolving my issues.

17 June 2025

R

Ryan Hudson

I highly recommend this product! Quality combined with excellent service.

09 May 2025

Wheel Loader

Wheel Loader  Excavator

Excavator  Motor Grader

Motor Grader  Backhoe Loader

Backhoe Loader  Road Roller

Road Roller  Spare Parts

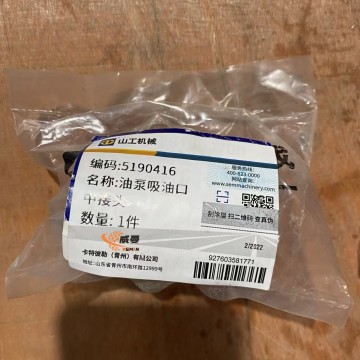

Spare Parts