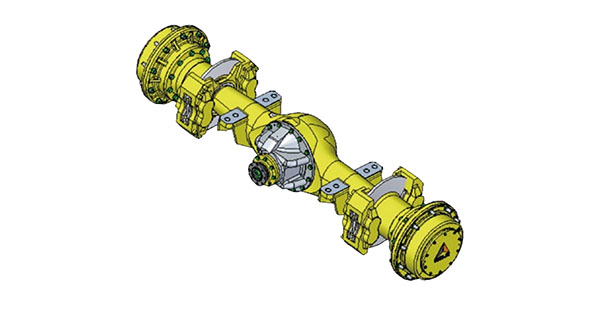

High-Quality Hydraulic Cylinder Boom from Top Chinese Manufacturers and Factories

Quality and reliability are essential when sourcing hydraulic components. Our Hydraulic Cylinder Boom is engineered for superior performance, making it suitable for a range of industrial applications. By offering competitive wholesale pricing, I ensure that you obtain the best value for your investment. Collaborating with established suppliers and a trusted factory, we deliver durable products tailored to your requirements. This hydraulic cylinder boom is built to support heavy loads while ensuring smooth operation, making it a vital component of your machinery.

10 Essential Tips For Hydraulic Cylinder Boom Service Backed by Expertise Application

When it comes to maintaining hydraulic cylinder boom equipment, understanding the nuances of service and care is essential for extending its lifespan and ensuring optimal performance. Here are ten essential tips backed by industry expertise that will help you keep your hydraulic systems running smoothly. Firstly, regular inspection of hydraulic cylinders is key; check for leaks, corrosion, and any signs of wear that can lead to potential failures. Secondly, ensure that you maintain proper fluid levels and quality—contaminated or incorrect hydraulic fluids can cause significant damage. Thirdly, it's important to clean the cylinder rods before retracting them to prevent dirt and debris from entering the hydraulic system. Fourthly, utilize appropriate fittings and hoses that match the specifications of your equipment; mismatched components can lead to inefficiency and potential hazards. Additionally, ensure that the hydraulic system is adequately vented to prevent pressure build-up, which can result in catastrophic failures. Frequent maintenance checks, including testing Seals and replacing them as necessary, can significantly reduce downtime and repair costs. Lastly, operator training cannot be overlooked. Ensure that all personnel are adequately trained in the operation and basic maintenance of hydraulic equipment. This not only enhances safety but can also lead to more efficient operation. By following these expert-backed tips, you’ll ensure that your hydraulic cylinder boom equipment remains reliable and efficient, ultimately leading to enhanced productivity and reduced operational costs.

10 Essential Tips For Hydraulic Cylinder Boom Service Backed by Expertise Application

| Tip | Description | Frequency | Expert Recommendation |

|---|---|---|---|

| Check for Leaks | Inspect hoses and connections for signs of fluid leakage. | Monthly | Prioritize immediate repair to prevent system failure. |

| Fluid Quality | Monitor oil quality and change if contamination is detected. | Quarterly | Use test strips to check for degradation. |

| Cylinder Alignment | Ensure proper alignment of hydraulic cylinders. | Every service | Misalignment can cause premature wear. |

| Seal Maintenance | Inspect seals for wear and replace as needed. | Annually | Select high-quality seals for better longevity. |

| Pressure Checks | Regularly check system pressure against specifications. | Monthly | Use calibrated gauges for accurate readings. |

| Proper Storage | Store cylinders in a clean and dry environment. | Always | Minimize exposure to extreme temperatures. |

| Cylinder Inspection | Inspect for dents, bends, or other deformities. | Bi-monthly | Deformities can impact performance significantly. |

| Hydraulic Hose Checks | Inspect hoses for signs of wear, kinking, or damage. | Monthly | Replace damaged hoses to ensure system efficiency. |

| Retraining | Provide ongoing training for staff on system operation. | Annually | Ensure all staff are familiar with safety protocols. |

| Consult Experts | Seek expert evaluation for persistent issues. | As needed | Don't hesitate to leverage expert advice for complex problems. |

Not to Be Missed Hydraulic Cylinder Boom Your Trusted OEM Partner Sets the Industry Standard

B

Benjamin Lee

Very pleased with my order. The support team provided expert guidance when needed.

24 May 2025

Z

Zoe Allen

I’m thoroughly satisfied! The product quality is exceptional, and service was impeccable.

23 May 2025

G

Gabriel Nguyen

The product quality is fantastic! The after-sales team provided excellent support.

26 June 2025

E

Eli Cooper

This product is a fantastic investment! Qualified support helped me significantly.

26 May 2025

S

Sebastian Reyes

High-quality and reliable! The service personnel were professional and attentive.

23 May 2025

W

Wyatt Reed

Top-tier quality! The service staff was professional and truly supportive.

06 June 2025

Wheel Loader

Wheel Loader  Excavator

Excavator  Motor Grader

Motor Grader  Backhoe Loader

Backhoe Loader  Road Roller

Road Roller  Spare Parts

Spare Parts